Through revised industry standards, technological advancements, and increased government regulations, the complexity of commercial vehicles is on the rise.

The increase in vehicle complexity leads to more components that can cause issues and more components technicians must learn to diagnose and repair. Technicians faced a sharp learning curve with the introduction of EPA 2007/2010 heavy-duty engine and vehicle standards.

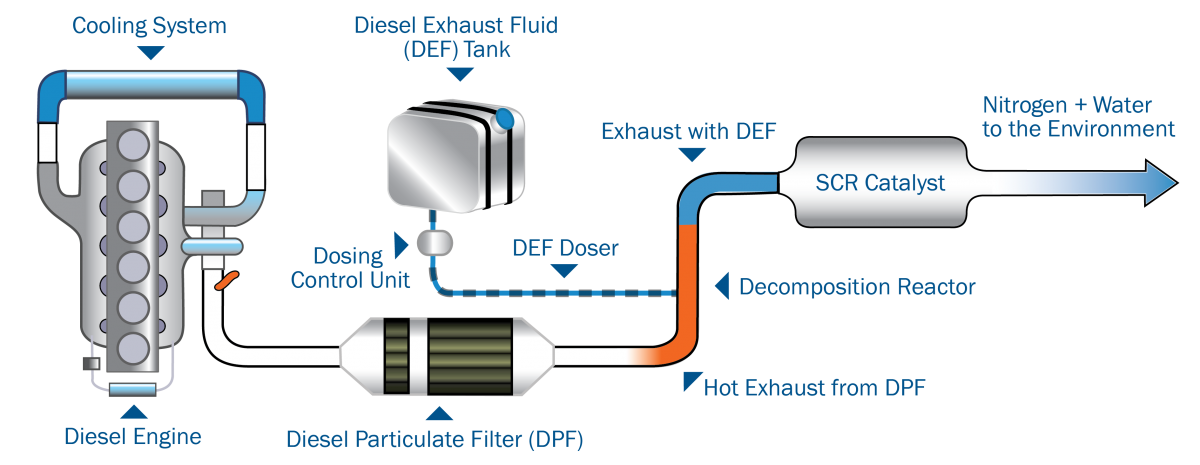

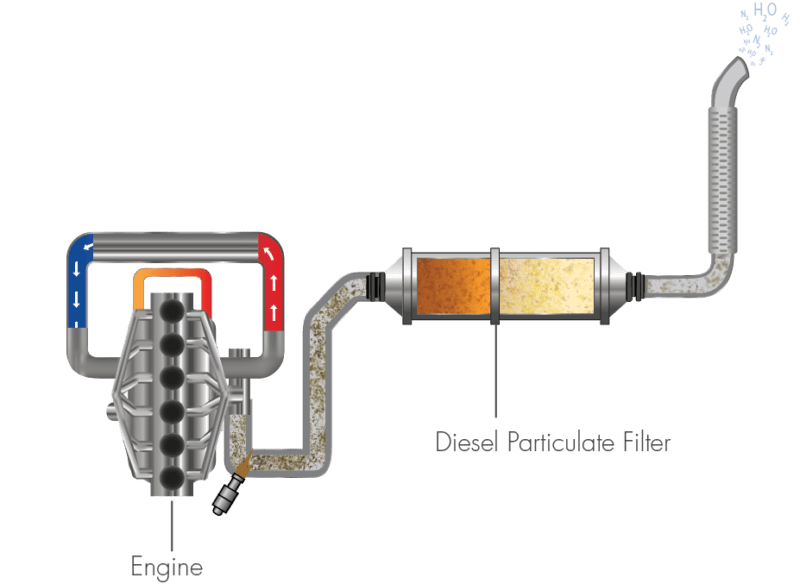

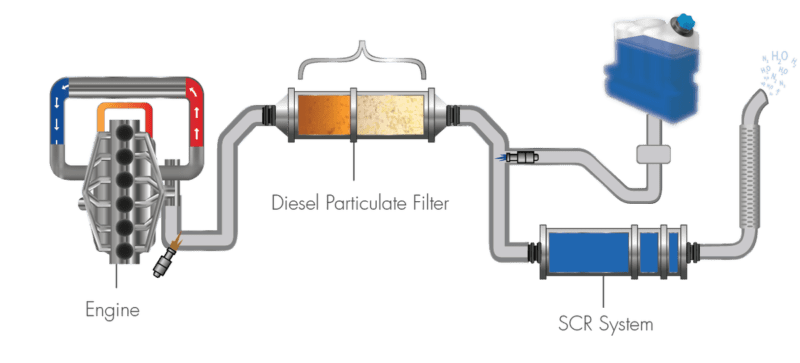

These standards required that all vehicles beginning with the 2007 model year have a diesel particulate filter (DPF) and 50% of engines would require nitrogen oxides (NOx) exhaust control technology. Beginning with 2010 models, NOx exhaust control technology was mandatory on 100% of heavy-duty diesel engines.

NEW EPA STANDARDS

The EPA introduced these standards to reduce particulate matter and NOx values to significantly low levels. Due to self-inspection in the trucking industry, the regulations required that foregoing repairs on emission related problems could result in the truck severely derating and leading to a breakdown.

Not only did these new standards increase the manufacturing and operating costs of vehicles, they forced the introduction of new systems for technicians to learn how to maintain or repair. To meet the requirements, many vehicle manufacturers began pairing a selective catalytic reduction (SCR) system with their DPF system. These installments met the requirements of the EPA and even had a positive effect on fuel economy in some vehicles, but also created many new potential faults for the vehicle to register.

2003-2007 EGR Only

Exhaust Gas Recirculation (EGR)

2008-2010 DPF Only

Diesel Particulate Filter (DPF) Exhaust Gas Recirculation (EGR)

2011-2018 DPF SCR

Diesel Particulate Filter (DPF) Exhaust Gas Recirculation (EGR) Selective catalytic reduction (SCR)

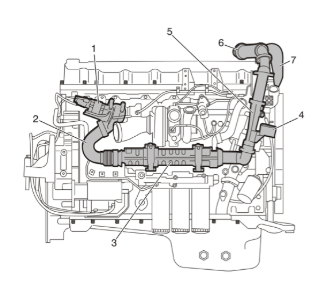

1. EGR System

An EGR valve is mounted on the exhaust manifold. This valve regulates exhaust gases that go into the engine. A portion of the exhaust gases is re-directed from the EGR cooler, through various pipes and routes into the intake manifold. This has a temperature sensor, differential pressure to sense the flow of the air coming in.

This EGR system works with the VGT operation to create the right turbo drive pressures for the right amount of EGR Flow.

The 2003-2007 EGR systems on the older engine models do not have a VGT Turbo, so this EGR operation will work the same way but without regulating the turbocharger.

2. DPF System

The exhaust aftertreatment system also consists of two parts designed to increase exhaust temperature for proper DPF regeneration. The aftertreatment Fuel Injector (AFI), mounted on the exit pipe from the turbocharger, injects diesel fuel into the exhaust stream during a regeneration cycle. When the fuel contacts the Diesel Oxidation Catalyst (DOC), a chemical reaction occurs, and the exhaust system temperature increases to a level that oxidizes the soot in the filter and reduces the emission out the tailpipe.

Under normal engine operation, the DPF collects soot and other particulate matter. These will be eventually oxidized using a regeneration process. The DPF filter can show sign of failure such as:

- Temp Regeneration Lockout

- Parked Regeneration Needed

- High Soot Load Fault Codes (Level 2, 3, 4) 144%+

- Active DPF Fault Codes

- Excessive fuel mileage loss

- Performance Loss

3. SCR / DEF System

The system will have the SCR system, DPF filter, EGR system and VGT turbocharger to regulate emissions. The SCR technology allows for passive regeneration. This occurs when the EGT at the DPF inlet and the NOx Ratio to soot ratio are high enough to oxidize the particulate matter. The process is slow and does not change the engine operation.

With this system forced stationary regeneration is only a backup when passive regeneration is insufficient. The soot ratio will increase and decrease depending on the operation of your system.

4. VGT Turbo Charger

The VGT regulates the charge pressure and drives the exhaust gas recirculation (EGR) system. The turbocharger speed is controlled by an electronic actuator and will adjust based on engine load conditions .

Benefits

Lowers emissions

Better fuel consumption

Increases power output

Common Problems

Active Faults for VGT

No pulling power / Derated

Costly repair

5. Testing

FCAR Diagnostic Scanner will help to found issue:

- Diesel Particulate Filter Service Regeneration

- Exhaust Aftertreatment Diagnostics

- Variable Geometry Turbocharger, Function Test

- Exhaust Gas Recirculation, Function Test

- SCR System Test

- DPF Soot Reset

- Engine Learned Data Reset

These tests can be conducted to see what issues you are having with your system.

By examining aftertreatment fault data starting in 2007 and DEF/SCR faults beginning in 2010, we discovered that 60% of all repairs are regen-related. We also discovered that the SCR system fails more commonly than any other powertrain related system. These findings mean that, beginning in 2007, the most common issue in the shop is one an experienced technician likely received no training for in school, illustrating the importance of ongoing training. With no method to clean an SCR system properly, replacements are more common than with other vehicle systems. On average, these systems cost around $4,000 to replace on a heavy-duty vehicle. If your current maintenance plan is managing replacement intervals of 450,000 miles, that equals one new SCR system per year for many fleets. Multiply that by the number of vehicles in the fleet and you will recognize why improving maintenance on these systems represents significant cost-savings for fleets.